The Best Shed for Riding Lawn Mower 2026

Picture this: It's November. Your $5,000 riding lawn mower sits outside under a blue tarp that's already torn at the corners. The dealer who sold it to you never mentioned that exposure to moisture causes the deck to rust from the inside out—a process already beginning underneath those grass clippings you meant to clean off last month.

Here's what the equipment manufacturers know but rarely advertise: storing a riding mower outdoors cuts its lifespan nearly in half. Water infiltrates the engine through the air intake. Mice nest in the wiring harness. UV radiation cracks the seat and degrades every plastic component. The battery dies every winter, the belts rot, and that expensive mulching deck develops rust that spreads like wildfire once it starts.

Where do you store the grass-eating monster?

The American garage, that great monument to suburban storage dysfunction, already houses two cars, fourteen bicycles in various states of repair, and approximately 47 boxes labeled "misc." The riding mower gets exiled to the elements, where a $5,000 machine receives the same protection as a bag of mulch.

This is the storage shed industrial complex at work—not a conspiracy, just market physics. Shed manufacturers know you need the space. You know you need the space. But between the 73 different models, four construction materials, and price points ranging from "suspicious" to "small mortgage," paralysis sets in. Another season passes. The tarp gets replaced. The mower degrades.

We've tracked what people actually buy when they finally pull the trigger. Not what they should buy according to some marketing department, but what moves off Amazon's warehouses in real volume. The patterns are revealing: buyers split into three camps. The maintenance-free crowd goes resin (paying 30% more to never paint anything). The value hunters choose metal (accepting rust-watch duty for maximum cubic feet per dollar). The temporaries grab fabric-over-frame solutions that work exactly as long as you'd expect.

Price tells its own story. Under $500 gets you a steel box that needs constant vigilance against rust. $800-1,500 buys legitimate weather protection with resin construction that ignores the elements. Above $2,000 enters the realm of actual workshops disguised as sheds—places where zero-turns share space with welding equipment and questionable renovation projects.

What follows isn't shed poetry or lifestyle aspiration. It's pattern recognition from thousands of purchases, assembled into something useful. Each shed category below solves a specific problem for a specific user at a specific price point. The only question is which problem is yours.

The Market Reality Check

Before we dive into specific models, let's address what's actually happening in the shed market circa 2026. The resin shed revolution that started ten years ago has reached maturity—Suncast and Lifetime essentially own the space through Amazon, having figured out the sweet spot between "cheap enough to offer a limited amount of protection" and "sturdy enough to survive a decade."

Metal sheds occupy a weird middle ground. They're cheaper than resin but require actual maintenance (remember painting things?). Arrow dominates here through sheer volume and the fact that their wood-grain printed steel somehow convinces people they're buying the aesthetic of a barn without the rot issues of actual wood.

Then there's the fabric shed underground—ShelterLogic's domain—where people who need six months of protection max can spend $200 and call it done. These buyers either have temporary situations or haven't yet learned what "waterproof" means in marketing versus reality.

| Mower Size | Featured Product | What It Actually Does | Click Image to Read Review |

|---|---|---|---|

| Medium-Large | Suncast BMS8130 Tremont Storage Shed | The suburban standard—handles 90% of riding mowers without drama |  |

| Large | Lifetime 60236 Outdoor Storage Shed | Workshop pretending to be a shed—for people with actual land |  |

| Medium | Suncast 8′ x 10′ Tremont Storage Shed | The compromise—fits standard lots |  |

| Medium | Keter Factor 8x11 Outdoor Storage Shed | Premium features with customizable wall system |  |

| Small | Rubbermaid Storage Shed Slide-Lid | The sliding roof nobody asked for but somehow works |  |

| Budget | ShelterLogic Shed-in-a-Box | Glorified tent that keeps rain off—nothing more, nothing less |  |

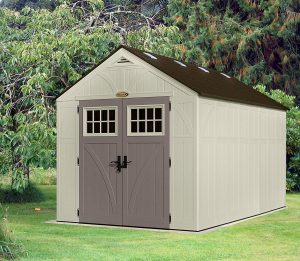

Medium-Large Riding Lawn Mower Shed: Suncast BMS8130 Tremont Storage Shed

The Suburban Standard

- 715 cubic feet storage capacity

- Reinforced floor (actually handles 2,000+ pound mowers)

- 8 skylights plus 2 windows

- 60" wide x 72" high door opening

- Blow-molded resin (the good kind)

- 10-year warranty (covers defects, not your mistakes)

This is the shed that launched a thousand suburban storage solutions. At 13' x 8', Suncast hit the Goldilocks zone—big enough for a real riding mower plus the inevitable accumulation of pool chemicals, fertilizer bags, and that leaf blower you use twice a year.

The construction method matters here. Blow-molded resin isn't the flimsy plastic of cheapo sheds that crack when you look at them wrong. This process creates panels with internal ribbing that actually support weight. Think Rubbermaid commercial products, not dollar store containers. The material laughs at weather—no rot, no rust, no annual painting ritual that nobody actually does.

The eight skylights seem excessive until you're trying to find a spark plug at dusk. Natural light transforms a dark box into usable space. The placement—four per side along the roofline—eliminates dark corners where spiders establish civilizations. Combined with the door windows, you get actual visibility without electricity.

Here's where engineering meets reality: the reinforced floor. Most shed floors are afterthoughts—thin sheets that develop soft spots where mower wheels park. Suncast reinforced the high-traffic areas and wheel paths. A 46-inch zero-turn (roughly 1,200 pounds) rolls in and out daily without creating permanent depressions. The 60-inch door width means you're not threading a needle every time—critical when you're tired and just want to park the thing.

Assembly requires what every shed requires: patience, a level foundation, and ideally someone who doesn't hate you after hour three. Figure 4-6 hours with two people who can read instructions. The pieces arrive numbered and pre-drilled. The manual uses actual photographs, not the hieroglyphics some companies pass off as instructions.

The foundation situation needs addressing because it's where most shed projects fail. Concrete pad: ideal but expensive ($400-600). Gravel base with pressure-treated frame: adequate and cheaper ($150-250). Directly on dirt: enjoy your funhouse doors that won't close within six months.

The warranty covers manufacturing defects for 10 years, which translates to "the plastic won't spontaneously disintegrate." It doesn't cover wind damage, installation errors, or that time you backed the mower into the wall. In practice, these sheds last 15-20 years with zero maintenance beyond hosing off dirt.

Real-world capacity: a 48-inch riding mower, push mower, wheelbarrow, and enough chemicals to qualify for an EPA inspection. The built-in shelf supports let you add organization without drilling into walls. Most users install 2x4 shelving for lighter items—the resin accepts screws despite what you might assume.

Check the latest price on Amazon

Large Riding Lawn Mower Shed: Lifetime 60236 Outdoor Storage Shed

The Small Barn Disguised as a Shed

- 1,376 cubic feet (basically a one-car garage)

- 9-foot wide tri-fold doors

- 15% taller than standard sheds

- Steel-reinforced everything

- 6 windows plus 2 skylights

- Shelving system included (actually useful)

At 11' x 18.5', this crosses into "structure" territory. Some municipalities require permits for anything over 200 square feet—this is 203.5. Check your local codes unless you enjoy conversations with building inspectors.

Lifetime went overboard with steel reinforcement, and that's not criticism. Steel tubes run through the walls, roof, and doors. The polyethylene panels are just weather protection—the steel does the structural work. This matters when snow loads hit or that derecho you weren't expecting rolls through. The shed handles 20 pounds per square foot snow load, which covers most of the continental US except Buffalo and the Rockies.

The tri-fold doors change the game for large equipment. Instead of squeeze-through double doors, you get a 9-foot opening—wide enough to drive through without holding your breath. The mechanism uses actual hardware, not the plastic hinges that plague cheaper sheds. Steel pins, steel reinforcement, and doors that still operate smoothly five years later according to the review patterns.

Height matters more than most people realize. Standard 8-foot sheds force tall people to duck. This runs 15% taller—enough that 6'2" users stop complaining about head clearance. More importantly, the extra height accommodates mowers with roll bars or grass catchers without dismantling anything.

Six windows plus skylights create legitimate workshop lighting. Not "I can sort of see" lighting, but actual "I can find the 10mm socket" visibility. The windows use shatterproof polycarbonate—not glass that breaks or acrylic that yellows. Screened vents handle airflow without inviting wasps to establish headquarters.

Assembly becomes a project at this scale. The manual runs 80+ pages. Components arrive in 5-7 boxes on different days because nobody coordinates freight anymore. Budget 8-10 hours with two competent people, or pay the $500-800 for professional assembly and preserve your marriage.

The foundation requirements escalate with size. A 200-square-foot concrete pad runs $1,000-1,500 professionally poured. The wooden platform alternative needs serious engineering—not just 2x4s on blocks. The weight distribution of a loaded shed plus equipment demands proper support or doors won't close by year two.

Inside, the included shelving handles actual weight—not the decorative plastic usually included. The corner units hold 50 pounds each. Wire shelving units fit between the steel supports for additional organization. Users commonly add pegboard to the steel frames, creating tool walls that don't require finding studs that don't exist.

This shed attracts two buyers: people with acreage who need equipment central, and suburbanites who've given up on garage space. Both report the same thing—it becomes the workshop the garage was supposed to be before it filled with life's detritus.

Check the latest price on Amazon

Medium Size Riding Mower Storage: Suncast 8′ x 10′ Tremont Storage Shed

The HOA-Friendly Compromise

- 547 cubic feet

- 60" door width (wider than most in this size)

- 6 skylights plus door windows

- Metal-reinforced roof (where it matters)

- Shingle-style appearance (HOA approved)

- Corner shelves included

The 8' x 10' footprint threads the needle between "useful" and "not an eyesore." This size fits behind most suburban houses without dominating the yard or triggering neighbor complaints about property values.

The critical measurement here isn't the footprint—it's the door width. Suncast made theirs 60 inches, which sounds like nothing until you compare it to the 54-55 inch openings on competing sheds. That extra 5-6 inches eliminates the daily dance of perfect alignment just to park your mower. Users with 46-48 inch deck mowers report comfortable clearance instead of paint-scraping proximity.

The hybrid construction approach—resin panels with metal reinforcement in the roof—addresses the weakness of pure plastic sheds. Resin roofs can develop sag over time, especially with snow loads or tree debris. The steel reinforcement here prevents the gradual bow that makes doors stop closing properly after a few seasons.

The shingle-style roof panels serve aesthetic more than functional purposes, but aesthetics matter when your shed is visible from the kitchen window. The wood-grain texture on the walls continues the illusion. From 20 feet away, it passes for an actual building rather than a plastic box.

Six skylights distribute light better than you'd expect. The placement along both roof slopes eliminates the cave effect common in windowless sheds. Combined with door windows, you get functional visibility for finding equipment without phone flashlights.

Assembly runs 3-5 hours with two people who've assembled flat-pack furniture before. The instructions use numbered panels and actual photographs. Pro tip from the reviews: organize all hardware first and build on a calm day. Wind turns panels into sails.

The foundation can be simpler at this size. A level gravel pad with a treated lumber perimeter works fine—about $150-200 in materials if you do it yourself. Concrete is still better but not mandatory like with larger sheds. Just ensure proper drainage or enjoy a mud pit by spring.

Real capacity: a 42-46 inch riding mower, push mower, trimmer, blower, and reasonable chemical storage. The corner shelves handle lighter items. Most users add a small workbench along one wall for maintenance tasks.

The metal roof reinforcement shows its value in year three when other plastic sheds start showing fatigue. The roof maintains its shape, doors still align, and the whole structure remains square. This is the engineering that separates $1,000 sheds from $500 ones.

Check the latest price on Amazon

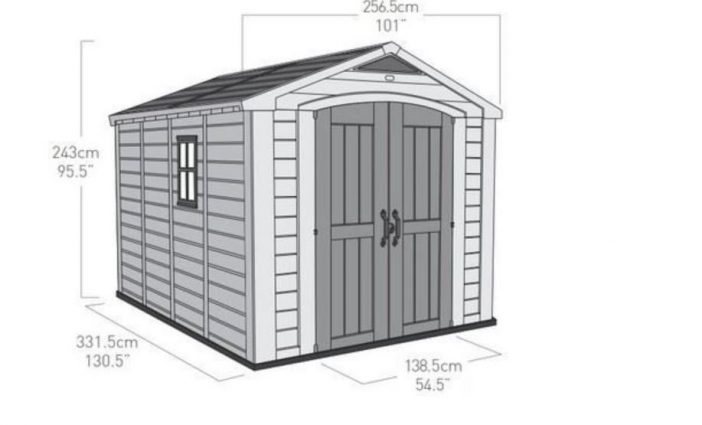

Alternative Option for Medium Size Riding Lawn Mower: Keter Factor 8x11 Outdoor Storage Shed

The Over-Engineered Import

- 550 cubic feet

- 54.5" door opening (narrower than Suncast)

- Full-length ridge skylight

- DuoTech walls (drillable/paintable)

- Steel reinforcement throughout

- 65 mph wind rating

Keter brings military shelter engineering to American backyards, and it shows. The DuoTech wall system lets you drill, screw, and paint the panels—try that with standard resin and watch it crack like a phone screen.

The full-length skylight running the entire roof ridge is either brilliant or excessive depending on your perspective. It creates museum-quality lighting inside but also represents a 10-foot potential leak point. Reviews split between "amazing natural light" and "started leaking in year two." Climate matters—works great in Arizona, potentially problematic in Seattle.

The door width issue can't be ignored—54.5 inches versus Suncast's 60. For a 42-inch mower, that's adequate. For a 48-inch zero-turn, that's threading a needle every single time. Measure your equipment including discharge chutes and bag attachments before committing.

Steel reinforcement throughout the structure provides legitimate storm resistance. The 65 mph wind rating isn't marketing fiction—it's tested with proper anchoring. The corner joints, door frame, and roof connections all feature steel brackets that competing sheds skip to save cost.

Assembly complexity jumps significantly. The DuoTech panels require different handling than basic resin. The steel reinforcement adds steps. Reviews consistently mention 6-8 hour assembly times and occasional missing parts. Keter's customer service gets mixed reviews—some receive replacements immediately, others fight for weeks.

The customization potential sets this apart. The walls accept standard screws and wall anchors. Users mount heavy tool racks, electrical boxes, even small air compressor systems. You can paint it any color, though few actually do. The panels take latex paint normally—no special plastic primer required.

Quality control varies more than American brands. Some units arrive perfect, others have warped panels or missing hardware. The manufacturing happens in Israel with global distribution—longer supply chains mean more opportunity for problems.

The shed either becomes someone's favorite purchase or a source of constant irritation. The engineering is superior when it works. When it doesn't, you're dealing with international customer service and hardware store workarounds.

Check the latest price on Amazon

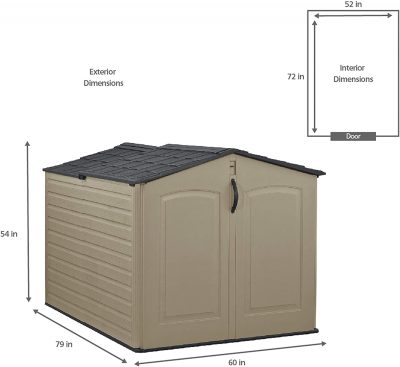

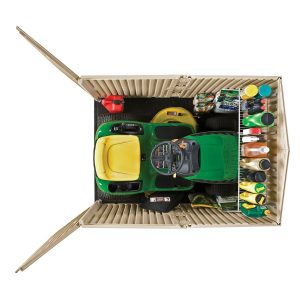

Budget Riding Mower Storage: Rubbermaid Storage Shed Slide-Lid

The Sliding Roof Nobody Asked For

- 96 cubic feet (smallest "real" shed option)

- Sliding roof on roller system

- 79" long x 60" wide x 54" high

- Double-wall construction

- Split barn doors with cane bolt lock

- 10-year limited warranty

Rubbermaid solved a problem nobody had: "What if we could access our shed from the top?" The sliding roof mechanism is either ingenious or absurd, depending on whether you've spent 20 minutes trying to extract a mower through the doors.

At 96 cubic feet, this fits compact riders and rear-engine mowers exclusively. Your nephew's Cub Cadet from 1992? Perfect. A modern 48-inch zero-turn? Not happening. The dimensions work for equipment under 48 inches long and 30 inches wide—measure twice, buy once.

The sliding roof's actual benefit: loading from above with a crane. Kidding—but it does help with seasonal storage access. Slide it back in November to extract the snowblower buried behind the mower. The roller system works smoothly when level but binds if your foundation settles even slightly.

Construction quality reflects Rubbermaid's commercial heritage. The double-wall panels resist impact and UV degradation better than single-wall alternatives. The plastic formulation doesn't get brittle in cold or soft in heat—problems that plague cheaper storage boxes.

Height limitations affect everything. At 54 inches exterior (42 inches interior at walls), you're ducking constantly. Riding mowers with high seats don't fit. Roll bars are out. Even sitting on the mower during storage requires slouching.

The foundation becomes critical because of the sliding mechanism. Any settling or tilting prevents the roof from sliding. Reviews consistently mention roof problems traced to foundation issues. A perfectly level concrete pad or meticulously leveled frame is mandatory, not optional.

Security exists but with caveats. The cane bolt locks the doors, but the sliding roof creates vulnerability. Someone could theoretically slide the roof open even with locked doors, though this requires knowledge of the mechanism and significant effort.

Assembly takes 2-3 hours with basic tools. The sliding roof mechanism requires precise alignment. Rush this step and enjoy a roof that sticks halfway open during the first rainstorm.

Real-world use: compact equipment only. Users with rear-engine riders report satisfaction. Users who "thought it would fit" their standard riding mower report disappointment and creative profanity.

Check the latest price on Amazon

Alternative Budget Option: ShelterLogic Shed-in-a-Box

The Expensive Tarp with Delusions

- 64 square feet (8' x 8' x 8')

- 1-3/8" steel tube frame

- Ripstop polyethylene cover

- Ratchet tensioning system

- Portable/temporary design

- Auger anchors included

Let's be honest about what this is: a tent for your mower. At under $300, it provides exactly $300 worth of protection. The frame is real steel with powder coating. The cover is legitimate ripstop fabric with UV inhibitors. Together, they create something that keeps rain off your equipment for about two years before the cover degrades into expensive confetti.

The target market is specific: renters who can't install permanent structures, seasonal storage needs, or people who haven't accepted that proper sheds cost real money. For these situations, it works exactly as well as you'd expect a fabric building to work.

The steel frame assembles like an erector set. Poles slot together, secured with bolts that will rust despite the "rust-resistant" coating. The frame alone is surprisingly sturdy—it's the cover that creates problems. Wind turns it into a sail. Snow accumulation causes collapse. Hail turns it into Swiss cheese.

Cover life depends entirely on climate. Arizona users report 5-8 years. Minnesota users measure in months. UV degradation is real—the fabric becomes progressively more brittle until it tears from normal tension. Replacement covers cost $150-200, making the long-term economics questionable.

Security doesn't exist. The zippered door is psychological at best. Anyone with scissors has full access in three seconds. This is weather protection, not theft prevention. Rural users report no issues. Urban users report missing equipment.

The auger anchors work in soil but not in rocky ground or hardpan. Without proper anchoring, the entire structure becomes a kite in moderate wind. Reviews include photos of frames wrapped around trees two yards over.

Setup takes 2-3 hours if you follow directions, 4-5 if you don't. The cover stretches over the frame and ratchets tight. Initial tension is critical—too loose and it flaps to death, too tight and seams tear.

Portability is the single genuine advantage. Disassembly takes an hour. The entire package fits in a car trunk. For temporary situations, this flexibility has value. For permanent storage, you're kidding yourself.

The two-year lifecycle is predictable: Year one works great. Year two shows wear—small tears, fading, loosening. Year three requires replacement cover or acceptance that you now own a metal frame sculpture.

Check the latest price on Amazon

Metal Sheds for Riding Lawn Mower Reviewed

The metal shed market exists in a strange parallel universe where people convince themselves that painting things annually is "not that bad" and rust is "character." But here's the thing—for pure dollars-per-square-foot value, nothing touches metal. You're trading convenience for capacity.

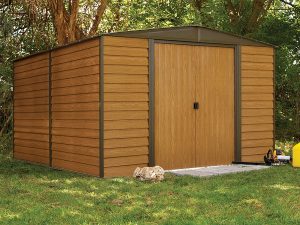

Arrow essentially owns this space through sheer volume and the fact that their wood-grain printed steel somehow looks less like a shipping container than raw galvanized alternatives. The printing technology is genuinely impressive—from your kitchen window, it passes for actual wood until you get close enough to see the pattern repeat.

| Mower Size | Featured Product | Reality Check | Click Image to Read Review |

|---|---|---|---|

| Medium-Large | Arrow WR108 Woodridge Steel Storage Shed | Wood appearance without the rot issues |  |

| Large | Arrow LX1014 Barn Style Steel Storage Shed | Maximum space for minimum investment |  |

Wood Effect Metal Shed: Arrow WR108 Woodridge Steel Storage Shed

The Metal Shed in Wood's Clothing

- 470 cubic feet

- 55" door opening (tight for larger mowers)

- 71" wall height

- Electro-galvanized steel with wood-grain printing

- Horizontal lap panel design

- 12-year limited warranty

Arrow's wood-grain printing technology deserves respect. From 20 feet, this genuinely looks like cedar siding. The horizontal lap panels complete the illusion. Your neighbors won't realize it's metal until they hear the rain drumming on it like a steel drum concert.

The 10' x 8' size handles standard riding mowers, but the 55-inch door opening creates daily frustration for anything over 46 inches wide. Users report the "suck-in-your-gut" maneuver becomes routine with larger equipment. Zero-turn owners consistently mention paint scrapes.

Electro-galvanization beats spray-on galvanizing, but let's be real—this will eventually rust. The zinc coating delays the inevitable by 5-10 years depending on climate. Coastal areas see rust in year three. Dry climates might get 15 years. The coating is prevention, not immunity.

Assembly reveals the classic metal shed experience: sharp edges, holes that don't quite align, and the discovery that you need three hands for certain steps. Budget 6-8 hours with someone who doesn't mind bleeding occasionally. Gloves aren't optional—they're mandatory unless you enjoy tetanus shots.

The wood-grain finish creates a specific problem: damage is permanent. Scratch the printing and you've got bare metal showing through fake wood grain. Touch-up paint helps but never matches. The finish survives normal use but not impacts from mower decks or wheelbarrow collisions.

Foundation requirements follow metal shed law: absolutely level or absolutely miserable. Metal doesn't flex like resin. A quarter-inch deviation means doors that won't close and panels that don't meet. Concrete is best, but a properly leveled wooden platform works.

Weather sealing requires attention. Metal sheds leak at every joint unless sealed properly during assembly. Clear silicone at panel overlaps prevents most water intrusion. Skip this step and enjoy interior rain during storms.

The 71-inch walls provide decent headroom, but the real issue is condensation. Metal sheds sweat like a cold beer in August. Without ventilation, everything inside stays damp. Adding vents helps but never eliminates the moisture completely.

Long-term ownership means annual inspection and touch-up. Check for rust at ground level where moisture accumulates. Seal any new scratches immediately. Oil door tracks and hinges. It's not overwhelming maintenance, but it's not zero either.

Check the latest price on Amazon

Large Capacity Metal Shed: Arrow LX1014 Barn Style Steel Storage Shed

The Barn That Thinks It's a Shed

- 852 cubic feet

- Gambrel roof with 7-foot peak

- Sliding doors (that will eventually stick)

- Galvanized steel with enamel finish

- 10' x 14' footprint

- 12-year warranty against perforation

At 10' x 14', this provides legitimate workshop space for under $700. That's the headline. The fine print involves 10+ hours of assembly, quality control roulette, and the guarantee that sliding doors will develop personality within two years.

The gambrel roof design maximizes interior height—over 7 feet at center. This matters for tall equipment and standing humans who prefer not developing permanent hunches. The barn profile also sheds snow better than flat designs, though snow load capacity remains modest at 20 pounds per square foot.

Quality control varies wildly between units. Some arrive with every hole aligned and all parts included. Others look like they survived shipping via trebuchet. Missing parts, bent panels, and pre-drilled holes that missed their mark by inches appear regularly in reviews. Arrow's customer service responds eventually, but "eventually" might mean weeks.

Assembly requires patience, experience, and ideally someone who's built one before. The instructions assume knowledge they shouldn't. Panel alignment is critical—get it wrong early and everything compounds. Professional assembly ($400-600) often costs nearly as much as the shed itself but prevents divorce proceedings.

The sliding doors work initially. Within a year, they develop character. The tracks collect debris, wheels wear flat spots, and suddenly opening requires a running start. Regular cleaning and lubrication extends function, but sliding mechanisms on budget sheds inevitably degrade.

Foundation requirements become critical at this size. The 140-square-foot footprint needs uniform support. Any settling creates structural stress that manifests as doors that won't close and roof panels that separate. Concrete is strongly preferred—wooden platforms work but require over-engineering.

Weather resistance depends entirely on assembly quality. Properly sealed panel joints resist water. Rushed assembly creates dozens of leak points. The galvanizing and enamel finish prevent rust for 5-10 years, but scratches and wear points need immediate attention.

The interior space justifies the hassles for many users. A full-size zero-turn mower fits with room for workbenches and organization. The height allows overhead storage that smaller sheds can't accommodate. It becomes the workshop/storage hybrid that the garage was supposed to be.

Long-term reviews split dramatically. Users who got good units and assembled carefully report 10+ years of solid service. Those who got bad units or rushed assembly describe ongoing frustration and premature replacement.

The value proposition is undeniable if you can handle the variables. No other option provides 850 cubic feet of covered space for $700. Just understand you're buying a kit that requires skill to become a functional building.

Check the latest price on Amazon

Frequently Asked Questions

What size shed do I need for a riding lawn mower?

Here's what manufacturers don't tell you: published mower dimensions lie through omission. That 46-inch deck measurement? Doesn't include the discharge chute sticking out 8 inches. The 70-inch length? Add 6 inches for the hitch you never removed. The height? Measured without you sitting on it.

Real measurements that matter: Your mower plus you sitting on it, discharge chute deployed, with any attachments you're too lazy to remove. Add 12 inches minimum on all sides for maneuvering room. That "perfect fit" 6' x 8' shed for your 42-inch mower becomes a daily geometry puzzle.

Industry practice suggests these minimums:

- Rear-engine riders (30-35" wide): 6' x 8' shed minimum

- Standard lawn tractors (42-48" wide): 8' x 10' shed minimum

- Zero-turn mowers (48-54" wide): 10' x 12' shed minimum

The door opening matters more than total space. A 54-inch door opening with a 48-inch mower means perfect alignment every time. A 60-inch opening means you can be tired, distracted, or slightly intoxicated (on coffee, of course) and still park without incident.

Do you need a foundation for a riding lawn mower shed?

Skip the foundation and here's your future: Doors that won't close by month six. Corners that separate during the first frost. A roof that develops creative new angles during spring thaw. The shed becomes modern art instead of functional storage.

Foundations distribute weight and prevent moisture wicking. A riding mower creates point loads of 300-400 pounds per wheel. Without proper support, shed floors develop permanent depressions that channel water directly to your equipment.

Cost reality:

- Concrete pad (professional): $3-5 per square foot ($300-500 for 8x10)

- Concrete pad (DIY): $1-2 per square foot ($100-200 for 8x10)

- Treated lumber frame with gravel: $150-250 DIY

- Directly on ground: Infinite frustration within one season

The lumber frame option works for sheds under 100 square feet. Larger sheds need concrete or significant engineering. Don't trust YouTube videos showing sheds on concrete blocks—that's for views, not longevity.

Can you put a plastic riding lawn mower shed on grass?

You can also eat soup with a fork—technically possible but missing the point. Grass under sheds dies, decomposes, and creates uneven settling. The moisture trapped between dead grass and shed floor accelerates equipment rust faster than outdoor storage.

Month 1: Everything seems fine Month 3: Doors stick slightly Month 6: Visible settling at corners Month 12: Doors require lifting to close Month 18: Structural warranty voided due to "improper installation"

If grass is your only option, minimum preparation includes:

- Remove all sod

- Add 4 inches of gravel

- Install treated lumber perimeter frame

- Ensure drainage away from shed

This costs nearly as much as proper foundation but performs worse. It's the compromise nobody's happy with.

Is a plastic shed better than a wooden shed?

"Better" depends on your tolerance for maintenance versus upfront cost. Here's the breakdown nobody gives you straight:

Plastic/Resin Sheds:

- Zero maintenance (literally hose it off annually)

- No rot, rust, or termite concerns

- 15-20 year lifespan with no intervention

- Costs 30-50% more initially

- Can't modify easily (drilling weakens structure)

- Color fading is permanent

Wooden Sheds:

- Requires annual treatment ($50-100 in materials)

- Rots without maintenance (5-7 year lifespan untreated)

- Infinitely repairable and modifiable

- Accepts standard hardware and modifications

- Can look fantastic or terrible depending on care

- Becomes a recurring project

The decision point: Do you want to think about your shed after assembly? No = plastic. Yes = wood.

Most people say they'll maintain wood then don't. Five years later they're buying plastic.

What maintenance do metal sheds require?

Metal shed manufacturers use phrases like "virtually maintenance-free" the way dating apps use "athletic build"—technically true but practically misleading. Here's the actual maintenance cycle:

Annual (minimum):

- Inspect for rust at ground level (where moisture accumulates)

- Check roof panel overlaps (where leaks start)

- Lubricate door tracks and hinges

- Touch up any scratches immediately

- Clear door tracks of debris

Every 3-5 years:

- Apply rust-preventive coating to wear areas

- Re-seal panel joints if leaking

- Replace worn door wheels/hardware

- Consider full repaint if finish is degrading

Climate-specific:

- Coastal areas: Double the inspection frequency

- Snow country: Check for ice damage each spring

- High humidity: Add ventilation or accept rust

The galvanized coating lasts 10-15 years in ideal conditions, 3-5 years in harsh climates. Once rust starts, it spreads like gossip in a small town. A $20 annual investment in prevention beats $500 replacement in five years.

The Bottom Line Nobody Wants to Admit

Here's what the reviews reveal after stripping away the marketing noise: Every shed type involves compromise. Resin costs more but delivers peace of mind. Metal provides space per dollar but demands vigilance. Fabric solutions work temporarily exactly as long as you'd expect fabric to last outdoors.

The expensive shed you buy once beats the cheap shed you buy twice. The foundation you do right beats the corners you cut. The maintenance you actually do beats the maintenance you plan to do.

Your riding mower cost thousands. The shed protects that investment or doesn't. Choose accordingly.

Final Thoughts: The Pattern Behind Every Purchase

The reviews tell the same story repeatedly: success comes from matching shed choice to actual needs and constraints. Frustration comes from wishful thinking about dimensions, skipping foundations, or choosing based on features rather than requirements.

Suncast and Lifetime dominate the resin category because they hit the sweet spot of features versus cost. Arrow keeps selling metal sheds because maximum cubic feet for minimum dollars still appeals to practical buyers. ShelterLogic serves the temporary storage crowd who need six months of protection without permanent structures.

Your choice comes down to three factors that nobody can decide but you:

Space constraints: That 10x14 shed looks great online but overwhelming in a 30-foot yard. Measure your available space, subtract two feet on all sides for maintenance access, and that's your maximum shed footprint.

Maintenance tolerance: Resin means never having to say "I should paint that." Metal means annual inspection and touch-ups. Wood means ongoing projects. Fabric means replacement every few years. Pick the relationship you want with your shed.

Budget reality: The shed costs what's on the price tag. The foundation adds 20-30%. Assembly adds time or money. Don't buy a $500 shed if your total budget is $500—you'll end up with a crooked shed on bare ground that becomes a neighborhood eyesore.

The riding mower shed market isn't complicated once you strip away the marketing. It's boxes that keep rain off equipment. Some boxes require less work than others. Some boxes cost more than others. Some boxes last longer than others.

Find the box that matches your specific equation of space, budget, and maintenance tolerance. The patterns from thousands of purchases show that when buyers match their actual needs to the right shed category, satisfaction follows. When they chase features they don't need or skip essentials like foundations, frustration follows.

Your mower is out there right now, waiting. The right shed for your situation exists in the categories above. The only question is which problem you're solving: space limits, maintenance avoidance, or budget constraints. Once you know that, the choice becomes clear.